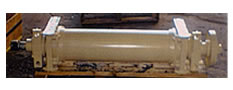

F Shaft Assembly

All Symons F and F60 Screens use the time-tested Symons Shaft Assembly to provide a positive reciprocating action that will not dampen out under heavy loads. A range of sizes is available with bearing sizes designed for particular applications.

Uses positive throw eccentrics integral with the shaft. Labyrinth seals provide positively sealed dust-proof and moisture-proof grease closures. Self-aligning spherical roller bearings, a standard in the vibrating screen industry, have been used since the first F models were developed. All bearing housings are held in positive alignment and the entire unit is balanced to carry the weight of the screen deck or load. Lubrication is by grease applied to one side of each bearing an allowed to escape through restricted clearances on the other side, providing thorough lubrication and cleansing of the bearing.

Capacity

To meet the need of larger screens requiring greater bearing capacities, heavy-duty Symons Shaft Assemblies are utilized. Larger units incorporate several important design improvements to provide heavy-duty long life service.

Alignment

A heavy center section of the shaft with integral counterbalance virtually eliminates shaft deflection and assures perfect alignment between the drive bearing housings. This allows the use of a straight roller bearing on one end, eliminating any possible end thrust on the drive bearings. The outer boxes are also held in positive alignment and use spherical bearings at both ends.

Clearances

All of the heavy duty Shaft Assemblies have greater clearances on the escape side of the bearing housings to allow for easy discharge of any excess amount of grease. This eliminates any heat buildup from an oversupply of grease.

Positioning

Bolted solidly to the balance deck and is flexibly connected to the screening deck by four drive springs, which translate the rotary eccentric action to the shaft to a positive reciprocating action to the screening deck, without the use of reciprocating bearings. Since the motion of the screening deck is opposed to that of the balance deck, very little vibration is transmitted to the base.

Housing

There is easy access to the main box bolts. The outer (main) boxes, as well as the inner (drive) boxes, are held in positive alignment.

New Assemblies

Symons stocks all the components required to make a new shaft assembly and can quickly turn an order into a shipment to reduce your downtime.

New assemblies typically have a 1-3 day lead-time with standard Symons warranty.

Required Assemblies

Symons also offers a full service repair facility to repair and return you shaft assemblies. Symons will disassemble your shaft assembly replacing only the parts that no longer meet OEM specifications. The shaft assembly will then be reassembled and shipped back to you. This option allows flexibility in keeping costs to a minimum.

Required assemblies typically have an estimated 5-7 day lead-time from receipt of the used assembly, with a 90-day warranty.

Exchange Assemblies

If you require the quicker turnaround of a new assembly but want to keep costs down, try the exchange program. Symons will provide you with a remanufactured shaft assembly from our inventory. This assembly can be put in operation immediately and your unit returned to Symons for rebuild. Symons will rebuild that unit, and charge you 90% of a new shaft assembly less credit for any usable parts from your old assembly. That assembly becomes available to send to the next customer.

Exchange assembly can typically be sent within 1-3 days lead-time from receipt of an order, with a 90-day warranty.