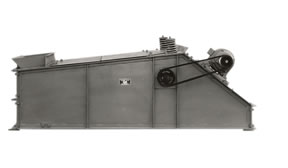

K Rod Deck Screen

The Symons K Rod Deck Screen has a screen surface composed of rods instead of the woven wire mesh or perforated plate commonly used as a screening medium.

The individual steel rods spring into place and held in position by molded rubber spacers. This patented screening surface is especially adapted to handle heavy feeds of wet sticky clay type ores on comparatively small openings.

Mine

Heavy Feeds

Wet

Sticky

Clay Ores

While the greatest field for the K Rod Deck Screen is mine screening, it is also applicable wherever sizing is not confined to square openings. Ideal for removing undersize from heavy tonnage crusher feeds in both closed and open circuit work. Designed for dry screening, wet material or with the use of water sprays.

The feed end of the screening deck is supported by a rubber rocker which constrains the motion to a line of vibration at approximately 30 degrees with the horizontal. The discharge end is floated on coil springs, allowing it to take the full motion imparted by the vibrator. This action and the slpe of the rods provides a quick getaway for the feed, but as it travels towards the discharge end, the thorough shakeup insures a rapid passage of all undersize. Particularly effective on gummy sticky material.

The proven Symons K Vibrator is located above at the discharge end with motor and drive placed outside the housing away from the dust. Drive is through a flexible coupling to the drive pulley. An optional direct drive feature is available as optional equipment including removable dust covers for easy access to the screening surface and the vibrator unit.

Economy

Low cost of screening due to the low cost and long life of the rods.

Saving in time and labor for replacements.

Great capacity of the screen in square footage available.

Capacity

The use of smooth parallel rods with openings 7" in length, permits the rapid passage of undersize material.

Unusual large capacity per square foot of area often cuts to half the number required as compared with conventional type screens.

Long Life

Oil tempered spring steel is very resistant to abrasions and the construction permits the use of comparatively large rods without cutting screening capacity.

Rods are smooth and straight so there are no crimped knuckles to wear off or break.

Replacement Ease

Individual rods or sections are easily replaced without disturbing the remainder of the deck surface.

All areas of the screening surface are easily accessible so there is no waste due to partial wear to another section.

Big Material

The strength of the screen surface and rigid support cushioned against shock by the molded rubber mounting, permits the handling of big material without damage to the screen.

Material to 5" max size can easily be handled.

| A | B | C | D | E | F | G | H | I | J | K | L | M | N |

| Screen Size | No. Decks | Weight lbs. | Feed in T.P.H. | Cloth Width | H.P. | Deck Length | Overall Height | Discharge Width | Base Length | Base Width | Opening | Rod# | Rod Sz |

| 3 x 6 | 1 | 3600 | 50-160 | 36 | 5 | 72" | 43 | 13 x 36 | 97 | 53 | 1/8 | 8 | .162 |

| 4 x 6 | 1 | 4000 | 70-215 | 48 | 7 1/2 | 72" | 45 | 21 x 48 | 107 | 64 | 3/16 | 6 | .192 |

| 4 x 8 | 1 | 4200 | 90-275 | 48 | 7 1/2 | 96" | 48 | 21 x 48 | 133 | 65 | 1/4 | 3 | .244 |

| 5 x 8 | 1 | 5300 | 115-345 | 60 | 7 1/2 | 96" | 48 | 21 x 60 | 133 | 73 | 5/16 | 3 | .244 |

| 3/8 | 3 | .244 | |||||||||||

| 7/16 | 3 | .244 | |||||||||||

| 1/2 | 0 | .307 | |||||||||||

| 5/8 | 0 | .307 | |||||||||||

| 3/4 | 0 | .307 | |||||||||||

| 1 | 0 | .307 |